Stanford professor Zhenan Bao and his team have invented a multi-layered, self-healing synthetic electronic skin that can recognize itself and align with each other when injured. Damaged or damaged synthetic leather can continue to work during the healing process. The new skin mimics reality, aiming to make robots feel like humans.

Stanford professor Zhenan Bao and his team have invented a multi-layered, self-healing synthetic electronic skin that can recognize itself and align with each other when injured. Damaged or damaged synthetic leather can continue to work during the healing process. The new skin mimics reality, aiming to make robots feel like humans.One step to the Terminator

This development is described as heralding a new era of robots and prosthetics with a human-like sense of touch, wrapped in self-healing synthetic materials. Chris Cooper, PhD candidate at Stanford University, along with postdoctoral researcher Sam Root, published this revolutionary development in the journal Science. “We have achieved what we believe is the first demonstration of a multi-layered, thin-film sensor that automatically realigns during healing. This is a critical step towards mimicking human skin, which has multiple layers that reassemble accurately during the healing process,” Cooper said in a statement. used the phrases.

This development is described as heralding a new era of robots and prosthetics with a human-like sense of touch, wrapped in self-healing synthetic materials. Chris Cooper, PhD candidate at Stanford University, along with postdoctoral researcher Sam Root, published this revolutionary development in the journal Science. “We have achieved what we believe is the first demonstration of a multi-layered, thin-film sensor that automatically realigns during healing. This is a critical step towards mimicking human skin, which has multiple layers that reassemble accurately during the healing process,” Cooper said in a statement. used the phrases.Layering is critical to mimic many of the skin’s features. “If you pierce, cut, or slice the synthetic leather, each layer will selectively heal within itself, restoring its overall function,” the researchers say. The process works just like real leather.

The team, led by Professor Zhenan Bao of Stanford University, says they can create multi-layered synthetic leather with individual functional layers, each as thin as a micron, perhaps less. So much so that a stack of 10 or more layers is no thicker than a sheet of paper. “One layer can sense pressure, another can sense temperature, and another can sense tension,” Root says. The material of the different layers can be designed to sense thermal, mechanical or electrical changes.

Recovery in 24 hours with new approach

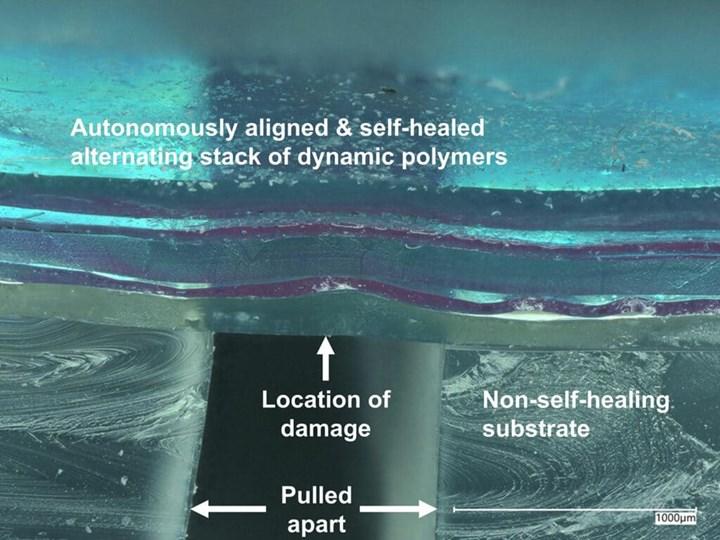

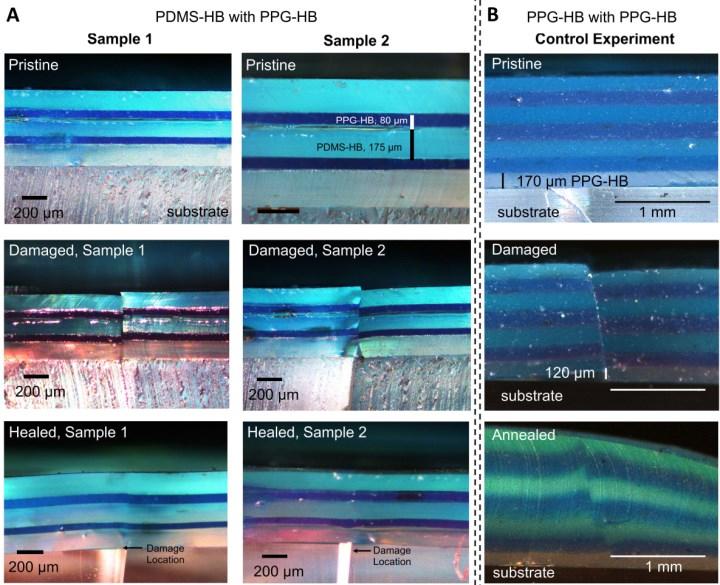

Professor Bao published the first multi-layered self-healing synthetic electronic skin study in Nature Nanotechnology in 2012. What sets their current work apart is that the layers recognize themselves and align with similar layers during the healing process, regaining functionality layer by layer as they heal. Existing self-healing synthetic leathers need to be manually realigned by humans. Even a slight misalignment in layers can compromise functional recovery.

Professor Bao published the first multi-layered self-healing synthetic electronic skin study in Nature Nanotechnology in 2012. What sets their current work apart is that the layers recognize themselves and align with similar layers during the healing process, regaining functionality layer by layer as they heal. Existing self-healing synthetic leathers need to be manually realigned by humans. Even a slight misalignment in layers can compromise functional recovery.The secret to achieving this lies in the materials. The researchers used the polymers PPG (polypropylene glycol) and PDMS (polydimethylsiloxane, more commonly known as silicone) in their new study. Both have rubber-like electrical and mechanical properties and biocompatibility. Both polymers have the advantage of softening and flowing when heated. When they cool, they solidify and become solid. Thus, the researchers were able to accelerate the healing process by heating the synthetic leather. Healing at room temperature can take up to a week, but when heated to just 70°C, self-alignment and healing occurs in about 24 hours.

Target self-assembling robots

After a successful prototype, the researchers, working with Professor Renee Zhao of Stanford University, added magnetic materials to the polymer layers, enabling the synthetic leather not only to heal but also to self-assemble from the individual parts.

As you can see in the Twitter video just above, the parts can be combined with each other with magnetic field guided navigation and induction heating. In the light of these developments, it is possible to build reconfigurable robots that can change shape and detect deformations when desired, at least according to the researchers.

“Our long-term vision is to create devices that can recover from extreme damage. For example, we envision a device that can autonomously reconfigure itself when it breaks apart and breaks,” says Cooper, showing a short video of several layers of synthetic leather submerged in water. The magnetically attracted pieces move towards each other and eventually rejoin. As they heal, their electrical conductivity returns.

medical use

In their next step, the researchers will work to make the layers as thin as possible and create layers with different functions. In terms of its vision for the future, the team envisions robots that could potentially be swallowed in pieces and then self-assembled inside the body to perform non-invasive medical treatments. Other applications include multi-sensory, self-healing synthetic skins and skins that adapt to robots and give them a tactile feel.