Samsung Electronics and TSMC are struggling to increase yield on the 3-nanometer (3nm, billionths of a meter) process, the most advanced process in semiconductor contract manufacturing. Both companies are reportedly still having trouble achieving a yield above 60 percent (the percentage of good products in total production).

Samsung Electronics and TSMC are struggling to increase yield on the 3-nanometer (3nm, billionths of a meter) process, the most advanced process in semiconductor contract manufacturing. Both companies are reportedly still having trouble achieving a yield above 60 percent (the percentage of good products in total production).Samsung and TSMC grapple with 3nm yield

As you know, the A17 Pro, produced in TSMC’s 3nm process, which was first applied to Apple’s iPhone 15 series, has been at the center of the overheating problem for a while. Although Apple states that there is no problem with the heating problem specifically for the A17 Pro, doubts are increasing. According to the semiconductor industry, both Samsung and TSMC’s 3-nanometer process yields are currently in the 50 percent range. This figure is interesting because in previous reports both companies were reported to have higher efficiency.

It was previously reported that Samsung Electronics had a 3-nanometer yield of over 60 percent and delivered these chips to a Chinese customer. The industry believes that the 3nm GAA (Gate-all-Around) technology that Samsung is focusing on has not yet reached the efficiency that will attract large customers. On the other hand, Samsung started mass production of 3nm GAA before TSMC, but it needs to secure a certain yield and establish a mass production system to attract large customers. According to reports, if Samsung wants to sell its 3nm chips to large customers such as Qualcomm, it needs to increase the efficiency to at least 70 percent.

It was previously reported that Samsung Electronics had a 3-nanometer yield of over 60 percent and delivered these chips to a Chinese customer. The industry believes that the 3nm GAA (Gate-all-Around) technology that Samsung is focusing on has not yet reached the efficiency that will attract large customers. On the other hand, Samsung started mass production of 3nm GAA before TSMC, but it needs to secure a certain yield and establish a mass production system to attract large customers. According to reports, if Samsung wants to sell its 3nm chips to large customers such as Qualcomm, it needs to increase the efficiency to at least 70 percent.3nm desired efficiency could not be achieved

It is reported that TSMC, the only company that currently has a 3nm mass production history, has low efficiency. While the iPhone 15 series is struggling with overheating issues, leading to speculation that TSMC’s 3nm process may be flawed, some analysts suggest that TSMC’s use of the FinFET structure used in previous generations of the process may have led to poor temperature control.

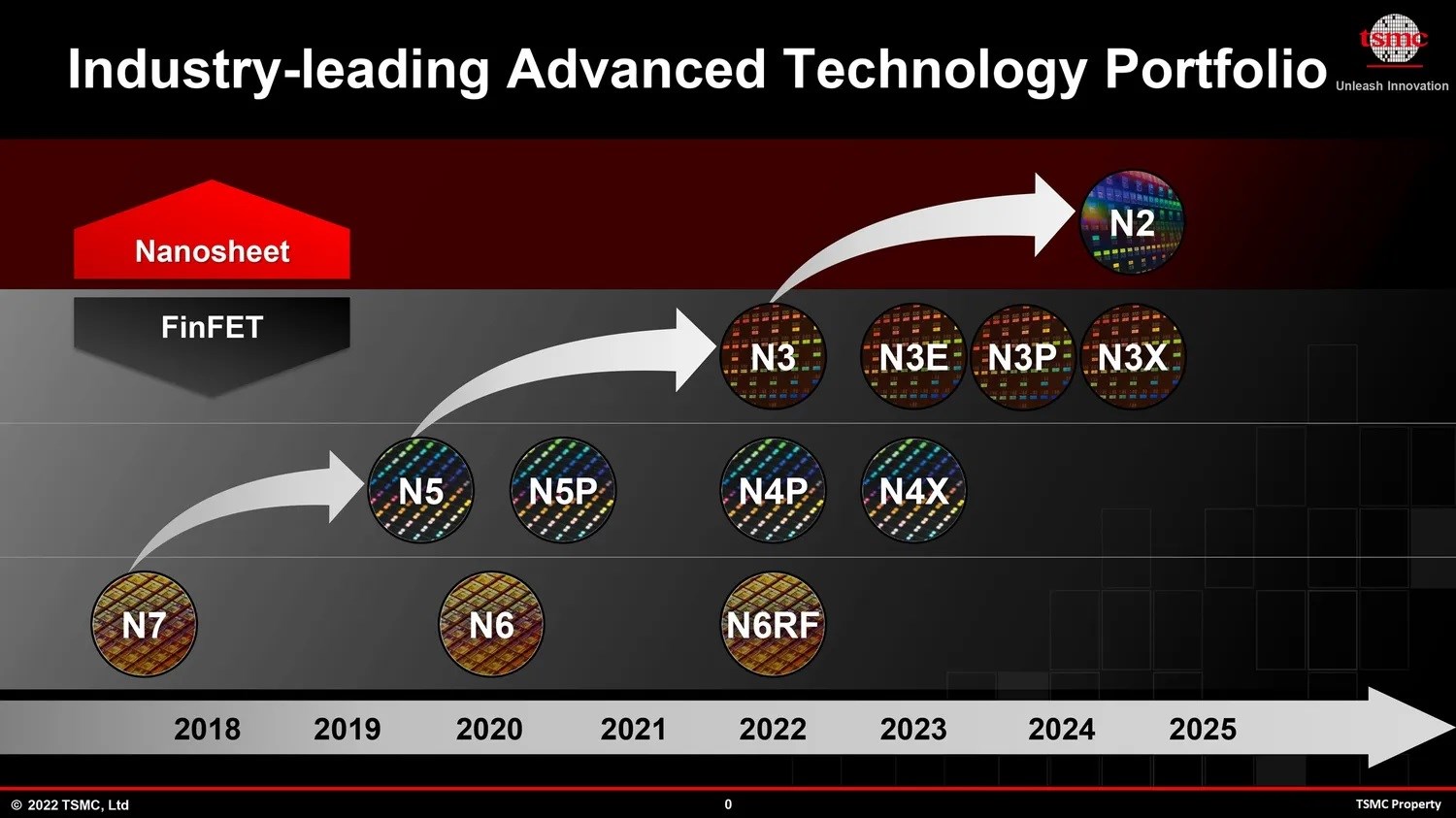

Experts believe that TSMC is still in the early stages of the 3nm process and may be an incomplete process. TSMC refers to the current process as N3. However, there are many more 3nm derivatives in future revisions, including N3E, N3P, N3X and N3AE, which are expected to go into full-scale mass production next year.

Experts believe that TSMC is still in the early stages of the 3nm process and may be an incomplete process. TSMC refers to the current process as N3. However, there are many more 3nm derivatives in future revisions, including N3E, N3P, N3X and N3AE, which are expected to go into full-scale mass production next year.The fact that there are so many derivatives indicates that 3nm may be one of the longest-lasting nodes. Samsung, TSMC and Intel are preparing 2nm processes, but the scope of performance and power efficiency improvement compared to 3nm is not large, so the demand for 3nm-based chips is expected to last longer than expected.

The race to secure 3nm yield will be decisive in the competition for mobile chips from Qualcomm and Samsung Electronics System LSI, which are expected to be released next year. Additionally, fabless companies that already use TSMC’s process, such as Nvidia and AMD, may shift some volume to Samsung to diversify their supply lines.