Researchers from the Faculty of Applied Sciences and Engineering at the University of Toronto have developed as solid as steel, but as light as styrofoam using machine education. This innovation can lead to a major change in many sectors from automotive to aviation.

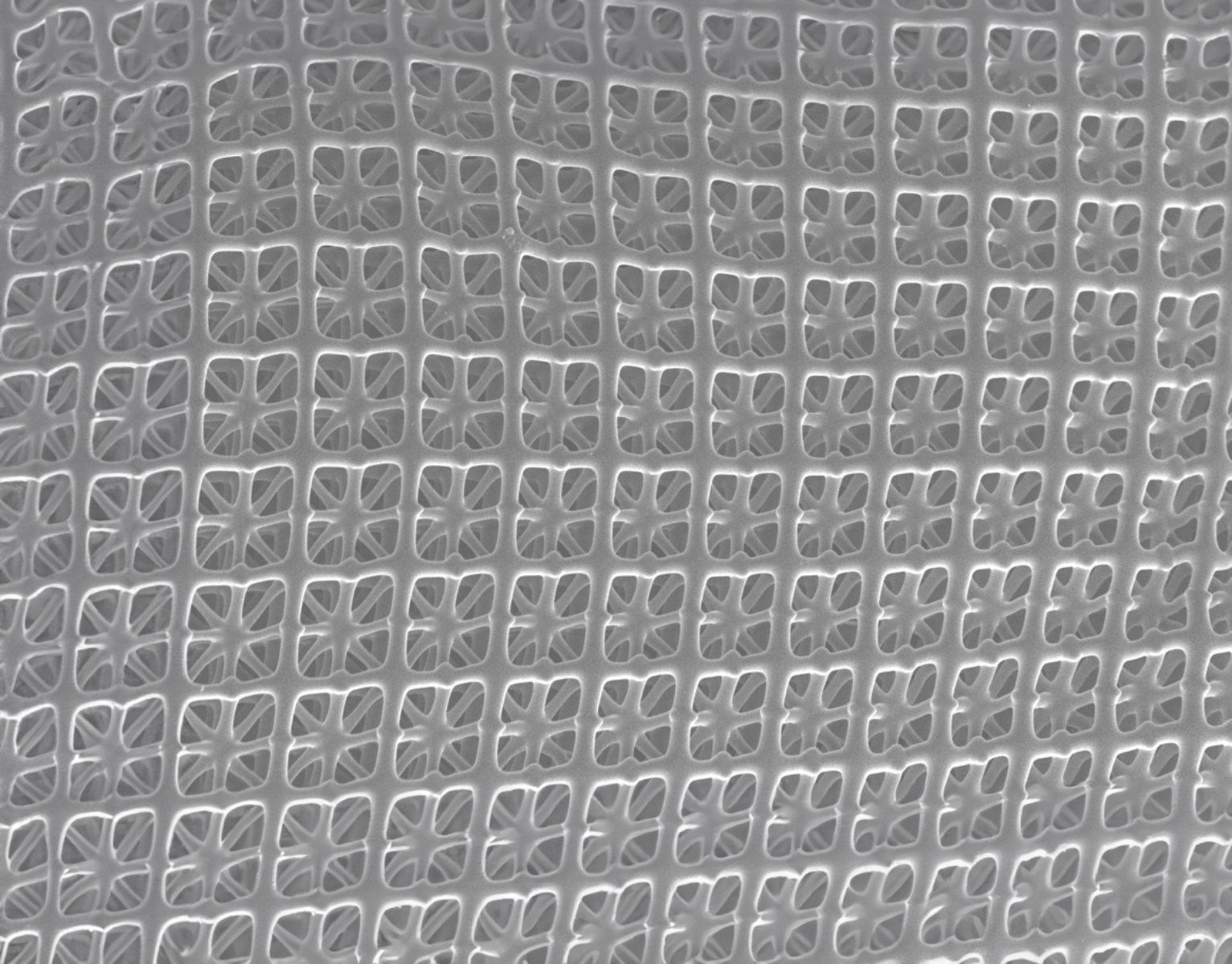

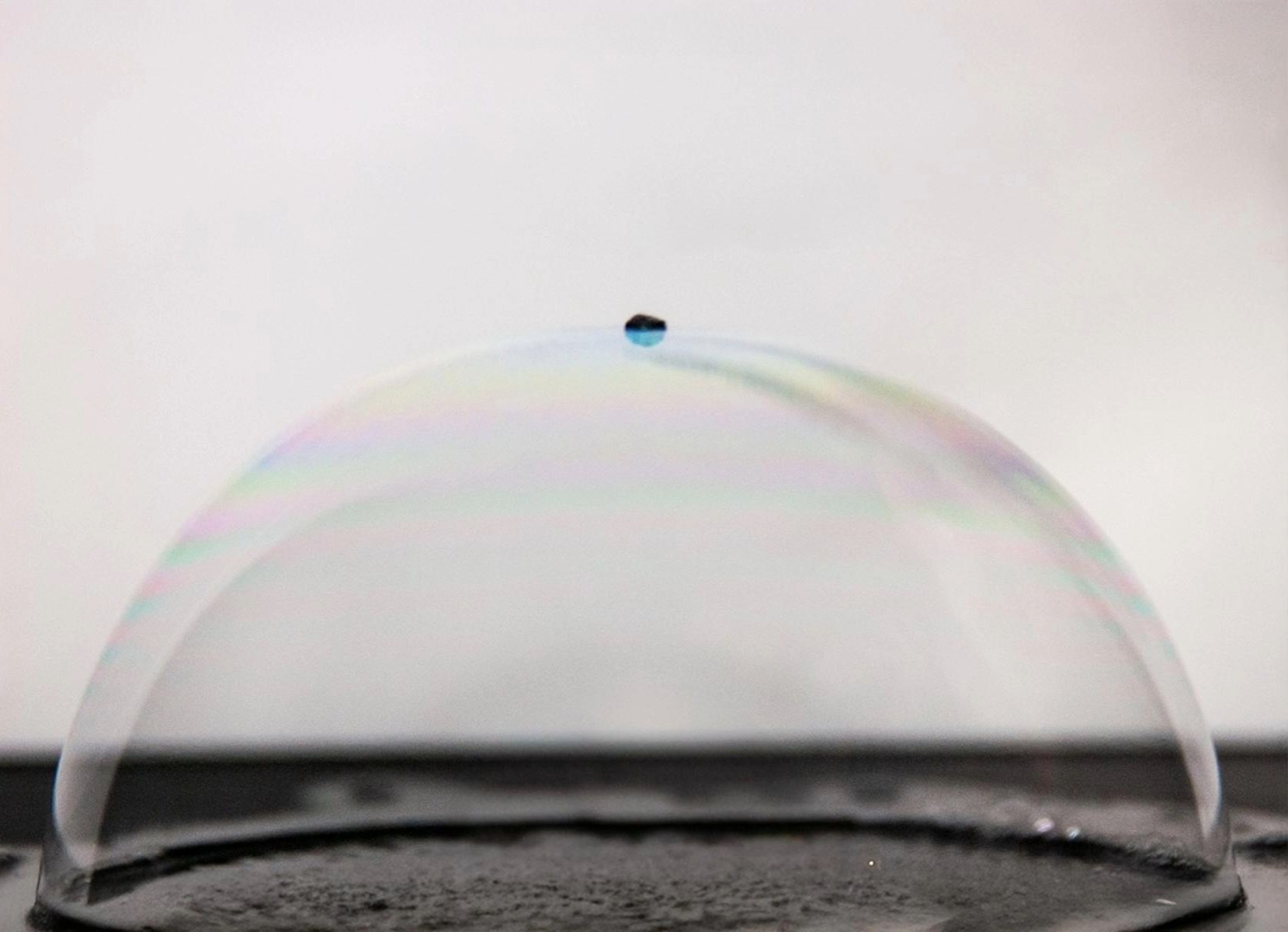

Researchers from the Faculty of Applied Sciences and Engineering at the University of Toronto have developed as solid as steel, but as light as styrofoam using machine education. This innovation can lead to a major change in many sectors from automotive to aviation.The team, led by Professor Tobin Filleter, managed to design nanomalyzems that offer extraordinary strength, lightness and privatizability. These materials consist of only a few hundred nanometers recurrent small building blocks. To compare, when 100 of them are lined up side by side, a person can reach the thickness of the hair strand.

5 times stronger than titanium

The team used the multi-purpose Bayesian Optimization Algorithm to optimize stress distribution of nano-square structures and increase durability. While this algorithm required only 400 data points, more than 20,000 data may be required in traditional methods. Thus, it was possible to work effectively with a smaller but high quality data set.

This experiment was the first experiment that scientists used machine education to optimize Nano architectural materials. Peter Serles, the chief author of the study, said that the results were surprised. The algorithm not only imitated previous successful designs, but envisaged completely new structures by analyzing which geometric changes worked.

This experiment was the first experiment that scientists used machine education to optimize Nano architectural materials. Peter Serles, the chief author of the study, said that the results were surprised. The algorithm not only imitated previous successful designs, but envisaged completely new structures by analyzing which geometric changes worked.Researchers produced prototypes for experimental verification using two photon polymerization 3D printers. As a result, the optimized carbon -based Nano materials double the durability of existing designs, and became five times stronger than titanium in durability per intensity.

Potential in aviation and automotive

Professor Filleter says these new materials can be used to produce ultra -light components in aircraft, helicopters and spacecraft. According to the researchers, the replacement of titanium components used in an aircraft with this new material can save 80 liters of fuel per year per kilogram. This has the potential to significantly reduce the carbon footprint of aviation. Similarly, the use of the automotive industry will reduce the weight of the vehicles and will allow the range to increase.