If you’ve ever wanted to fill up at a gas station, you may have wondered how the gas pump knows when to turn itself off. The answer to this question is surprisingly complex. You might expect a simple electronic detector that tells the pump handle to turn off when it gets wet, but the situation is quite different, as YouTuber and science communicator Steve Mold explains in a recent video.

Gasoline does not spill on the ground at the station, thanks to a phenomenon called the Venturi effect, discovered by Italian physicist Giovanni Venturi in 1797.

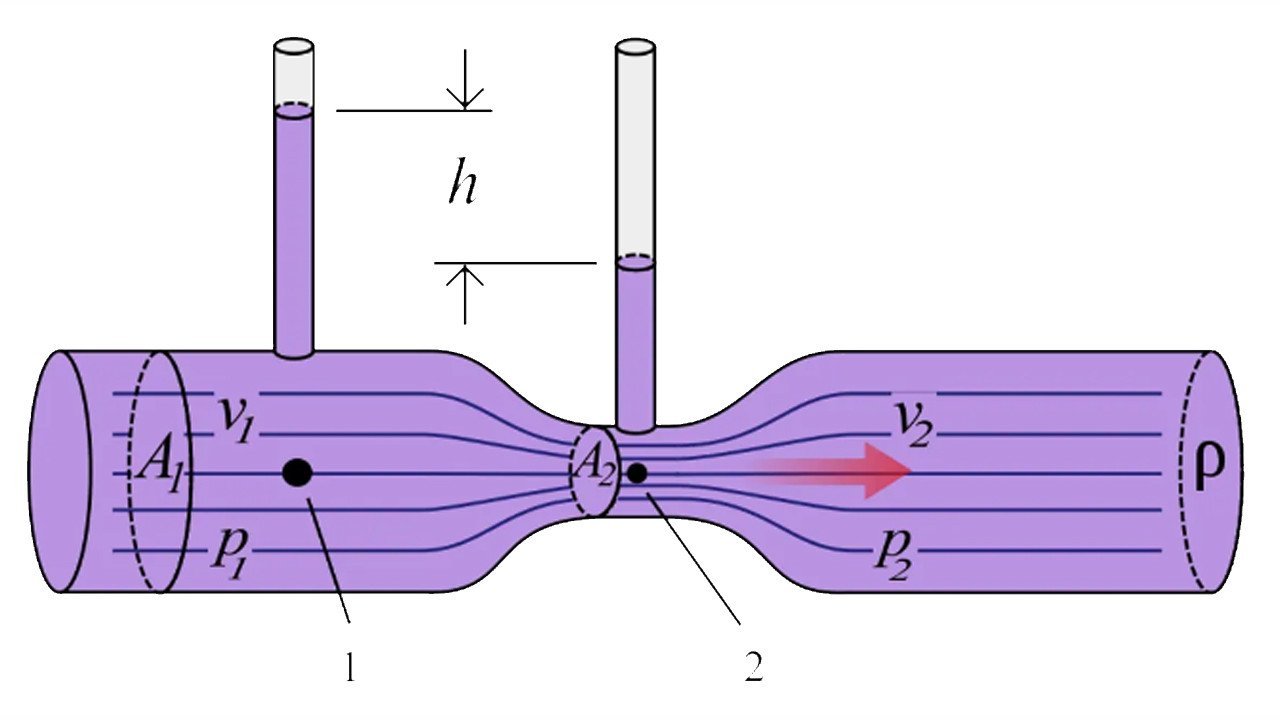

The basic idea behind the Venturi effect is that as the fluid passes through a narrow space (visible in the piping diagram above), the velocity of the fluid increases and its static pressure (shown using protruding tubes in the diagram above) decreases.

This principle is used in petrol pumps. You may have noticed a second, much smaller tube inside the pump nozzle. As Mold explains, this acts like pipe #2 above, entering the system through a constriction point.

Since the pressure in the narrowed part of the fuel pump is lower than atmospheric pressure, air is sucked in through the smaller nozzle and enters the system (gasoline is pumped into your car), thereby relieving some of the pressure.

This process continues until a certain point in your refueling process. This is when the smaller mouth touches the gasoline that fills your tank. The density of gasoline makes it difficult to transfer more gasoline.

The clever thing is to split the tube in two near the connection to the constriction in the tube. When the liquid blocks the small tube at the end of the spout, the suction power of the other split tube increases in response. While there are more add-on systems like ball bearings and a smart lever in the handle, the underlying thing is that this increase in suction pressure can be used to pull a membrane to close the main nozzle and stop dangerous gasoline spills.