Dyson Chief Engineer Jake Dyson, while creating the company’s software-based team in the published YouTube video; explains that the recently established team of software-based engineers is working on the next generation of smart, self-developing, connected products. The technology company, which is implementing its £2.75 billion investment plan in new technologies, says it puts software and connectivity at the center of its future product portfolio. He explains how designing products with software and connectivity can make users’ lives easier, and how users with Dyson technologies solve problems before they even realize that there is a problem with their machine.

With the tenfold growth in the number of software developers since 2012, Dyson machines are getting smarter and smarter using countless sensors, electronics, control systems and software code.

Thanks to its technology, Dyson products can make the invisible visible. For example, Dyson air purifiers detect and capture air pollution, keeping users informed about the air quality in their homes and informing future product developments. The latest Dyson Gen5detect vacuum offers precise data to the user by counting and sizing microscopic particles; It also shows areas of dust and dirt on the floor, an improvement over the more mechanical Dyson products from 10 years ago.

The goal is to design machines that get smarter as long as the user has them, that can self-identify, troubleshoot and fix problems before they realize something is wrong.

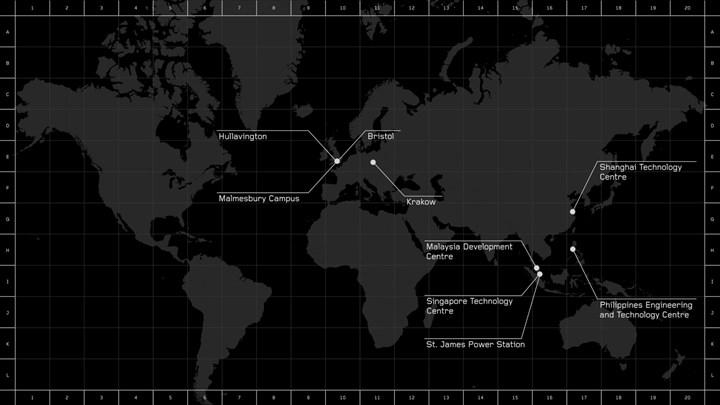

Dyson Chief Engineer Jake Dyson said: “Where software and data science is taking us isn’t about futile work or features that aren’t needed. It’s about bringing purpose to our technologies and making people’s lives easier. You don’t have to worry, we take care of your products. Top confidential and We have invested in our laboratories and campuses in the UK, Singapore, the Philippines and Poland for our engineering team working on sustainable smart technologies and growing with a 15-year plan.” said.

A 10-year software journey and beyond

Dyson has grown its software and connectivity team more than 10x in the UK, Singapore, Malaysia, Philippines, China and Poland over the past decade. This growth in expertise demonstrates a focus on making Dyson technologies smarter. This work extends beyond software. Dyson’s data scientists, robotics, electronics hardware and machine learning engineers work alongside software and form an important and growing part of the company’s total engineering team. Forty-five percent of early-career engineers at Dyson work in software-based teams.

Software used to be about controlling individual components, but is now critical in every function of Dyson technology. Embedded software, application and cloud development, embedded software layers, algorithms, machine learning and artificial intelligence in Dyson products enable them to do sophisticated things beyond mechanics, a key area where the industry has evolved over the past 10 years. With Dyson’s first vacuum, all you could do was start the engine. Dyson vacuums now provide information on battery life and adjust energy use based on floor type, thanks to a myriad of built-in sensors, electronic hardware and software.

Looking at the Dyson 360 Heurist robot vacuum; users no longer have to vacuum their own homes, the robot does it for them. With the MyDyson application, connectable product features and personalized trainings are easily delivered to users. Dyson leverages its capabilities with data science, which is the foundation of air purifiers and air science education.

Roland Krueger, Chairman of Dyson’s Board of Directors, said: “Dyson has begun rolling out a five-year £2.75 billion investment plan covering the UK, Singapore, Asia, Europe and Americas. We have announced that we will invest in new technologies such as. Now we are delivering on our promise. These investments will form the basis of expanding our product categories and completely new product areas for Dyson. Our ‘Digitization Journey’, which focuses on software capabilities across the company, is a key element of these investments and is turning a new page for Dyson. It will be effective.” said.

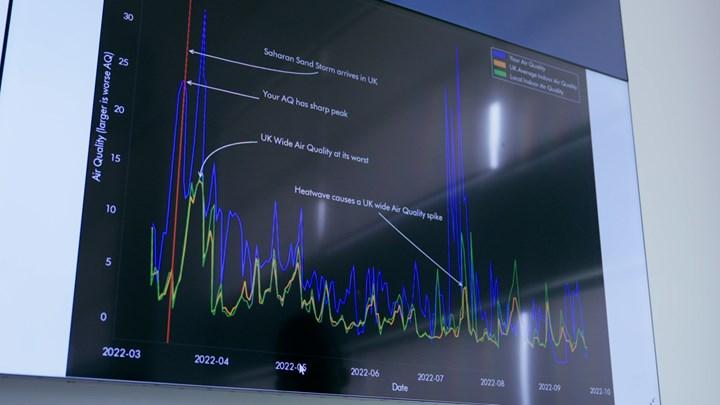

Education on exposure to pollution

Six years ago, Dyson made its first air purifier connectable, allowing users to monitor their home’s real-time air quality on the screen and from the app for the first time. Dyson engineers use this data, sensed by more than 4 million smart Dyson air purifiers, to map indoor air quality around the world. Live tracking of connectable machines means that Dyson can see pollution events that occur, and air cleaners can educate people about avoiding exposure to air pollution. Dyson engineers believe they are the first and only company in the world to be able to alert people of pollution events in their local area, such as wildfires or sandstorms, based on air quality data from Dyson air cleaners. Every day, 200 million air quality signals are sent from Dyson air cleaners to Dyson engineers, providing information about future research and training on personal exposure.

The soon-to-be-released Dyson Zone will use this technology to monitor and purify the air in your personal space on the go. Dyson Zone will be connected and the MyDyson app will provide real-time air quality and noise pollution data and weekly pollution trend reports. This will help educate and protect people to reduce their exposure to air pollution.

In addition to product development, Dyson collaborates with research institutions and academic institutions to develop a global understanding of air quality. Dyson engineers developed the connectable Dyson air quality backpack for the Breathe London Wearables project in 2019. 250 students donned backpacks equipped with particle and gas sensors, GPS and a battery pack to monitor their exposure to pollution on the streets of London to and from school, and 31 percent of children changed their way to school to minimize exposure to pollution. Smart backpacks are currently being used in six African countries in the Sahara region, Ghana, Malawi, Nigeria, South Africa, Tanzania, Uganda and Zimbabwe, as part of the CAPPA project led by Queen Mary University of London to understand asthma rates among African children.

future plans

Dyson has begun implementing its five-year £2.75 billion investment plan in new technologies, doubling its product portfolio by 2025. Electronic hardware, software and connectivity play a key role in this plan as Dyson takes a long-term view of designing self-developed products, incorporating increased intelligence into its technologies, MyDyson app and user experience.